SS Non Woven Fabric Ua Tshuab

Khoom npe:

SS-3200 PP SPUNBOND NONWOVEN FABRIC MAKING TSHUAB

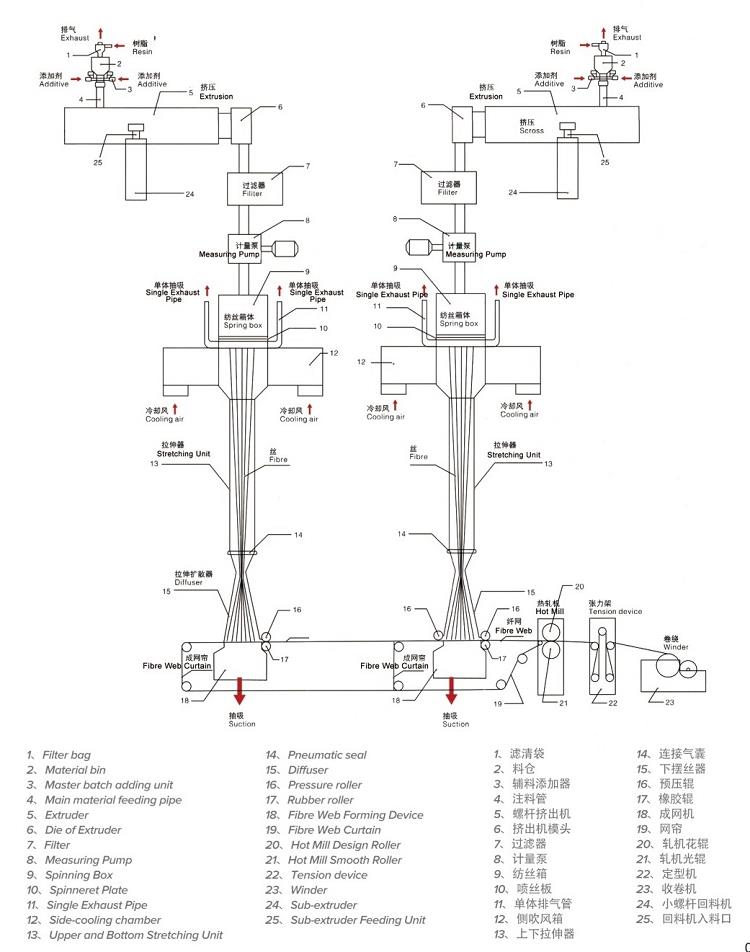

1. process flow:

Pub → Extrusion Melting → lim → ntsuas → spinning → txias → stretching → Web kis → Thermal bonding → slitting → sau

2. Khoom yam ntxwv:

2-1 Khoom PP spunbonded nonwovens

2-2 Khoom dav: 3200mm (tsawg kawg nonwoven khoom)

2-3 Cov khoom gram 14-120 g / m2

2-4 Filament titer: ≤2.5 Denier

2-5 Muaj peev xwm ntau lawm: 18T / Hnub (Raws li fabric≥40g / m2 )

3. raw khoom specification

3-1 Melting Performance index (g / 10min) 20-40

3-2 Melting point (0C) 165

3-3 Molecule uniformity degree (%)> 95

3-4 Grey piv (PPM) <200

4. Kev siv hluav taws xob

4-1 Hluav taws xob: 1312KW rau tag nrho cov kab, ua haujlwm fais fab: 495KW

| SN | Main khoom siv hluav taws xob | Lub zog ua haujlwm | Coefficient |

| 1 | Feeding Ntxuam | 5.5 KW × 2 | 0.5 |

| 2 | Master match meter | 0.75 KW × 6 | 0.4 |

| 3 | Extruder | 110 KW × 2 | 0.4 |

| 4 | Metering Pump | 5.5 KW × 2 | 0.5 |

| 5 | Kub roj voj voog system | 4 KW × 4 | 0.6 |

| 6 | Web qub & preheating cov menyuam | 36 KW × 1 | 0.3 |

| 7 | Calender | 22 KW × 2 | 0.5 |

| 8 | Roj voj voog system | 5.5 KW × 1 | 0.6 |

| 9 | Rewinder | 15 KW × 1 | 0.6 |

| 10 | Slitter | 11 KW × 1 | 0.3 |

| 11 | Sab cua txias blower | 75kWx 3 | 0.4 |

| 12 | Suction tshuab | 55 KW × 1 | 0.50 ib |

| 13 | Txias qhov system | 100 KW × 1 | 0.5 |

| 14 | Dej txias phuam | 15 KW × 1 | 0.6 |

| 15 | Calciner | 38 kWm | 0.3 |

| 16 | Ultrasonic nqus tsev vacuum | 2 KW | 0.4 |

| 17 | Hluav taws xob thaiv | 2 KW | 0.2 |

| 18 | Rhiav teeb pom kev zoo | 10 KW | 0.5 |

| 19 | Cua sov system | 492x1 qw | 0.4 |

| 20 | Cov khoom siv rov ua dua tshiab extruder | 18.5 KW × 2 | 0.3 |

4-2 Dej: 160m3/ hr ncig dej, 1T / hnub noj

4-3 Compressed cua: 1m3/ min.siab 0.8 Mpa

4-4 Cov neeg yuav khoom lub luag haujlwm feem:

A. Luas : 25 x 12 x 11 m

B.Lub hwj chim xa mus rau txhua yam khoom siv tswj txee

C. Dej xa mus rau cov khoom siv thiab teeb pom kev zoo ntawm cov nroj tsuag

D.Cov khoom siv, cov khoom siv hoisting thiab cov khoom siv thiab cov khoom siv yuav tsum tau ua

thaum lub sij hawm installation.

(Tus neeg yuav khoom yuav tsum muab kev pab thiab nyiaj hli ntawm tus neeg muag khoom tus kws tshaj lij.)

5. Cov duab ntxaws

|  |  |

|  |  |

6. Kev pabcuam

Kev Pabcuam:

A.Lsupportsourcustomersservice24hoursAday,7dayswork,Anyinquirycould

berepliedwithin1hourpre-salesandafter-muag.

WeBelievethatonly:BestQualityMachineWithInnovativeIdeasandExcellentAfter-maleService:”yuav tsum tau raws li koj qhov kev xav tau tshwj xeeb.

7. Qhov zoo

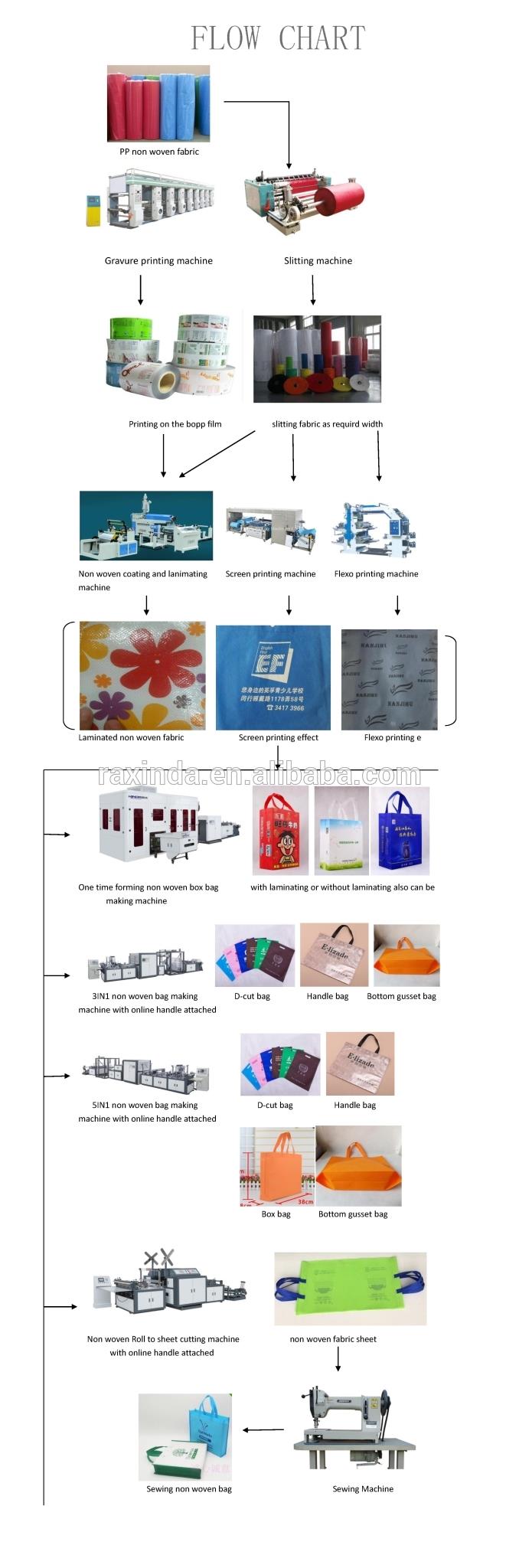

Kev siv cov ntaub nonwoven:

(1) Kev siv tshuaj kho mob thiab kev noj qab haus huv: kev ua haujlwm nplua, tsoos tsho, lub ntsej muag lub ntsej muag, daim pawm, cov ntaub so ntswg huv, cov khoom siv tu cev. thiab lwm yam;

(2) Kev kho kom zoo nkauj hauv tsev: lub hnab ntim khoom, cov ntaub npog phab ntsa, rooj ntaub, txaj ntawv, bedspread.etc;

(3) Hauv ob sab phlu rau khaub ncaws lossis khau: hauv ob sab phlu, nplaum interlining, khau hauv ob sab phlu. thiab lwm yam;

(4) Kev siv ua liaj ua teb: kev tiv thaiv npog, chaw zov me nyuam cover.etc;

Kev xaiv tshuab![]() unching khoom rau U-txiav hnab

unching khoom rau U-txiav hnab

Sib koom tshuab

Main tsis woven tshuab

Kev tswj xyuas zoo ua tib zoo saib xyuas txhua yam ntawm cov txheej txheem tsim khoom

Peb tau tsim cov qauv kev tswj hwm nruj nruj, qee qhov khoom siv tseem ceeb siv cov npe nrov txawv teb chaws los xyuas kom meej tias nws ua tau zoo ntawm txhua lub tshuab, tus nqi qis, durability, yooj yim thiab yooj yim khiav lag luam thiab tu, txhua yam los ntawm cov neeg siv khoom xav txog lub kaum ntse ntse.